This $13 Billion Aircraft Carrier Was Designed With 3D Models, Using AR Technology

Dhir Acharya - Dec 12, 2019

It will take over $13 billion to get this aircraft carrier ready for sale, its parts are designed with 3D models, and the crews aboard will use AR tech.

- This Dragonfly Plane Eliminates The Disadvantage Of Current Aircraft

- Top Most Famous Helicopters In The Indian Air Force

- Boeing 757 Engine Becomes A Massive BBQ Grill With Delta Techs

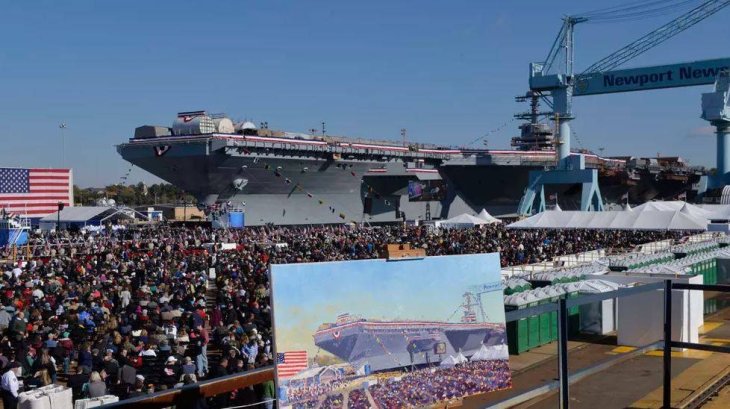

In the photo below is an aircraft carrier dubbed USS Gerald R.Ford, which is the first next-generation warship of the US. It was officially commissioned in 2017.

In November 2013, it was launched to start its trials. And though it was commissioned two years ago, the USS Gerald R.Ford needs four more years of trials before it gets deployed, meaning it won’t set sail till 2021. And the trials will add $780 million more to its cost.

The Ford features a massive size, is 337 meters long and over 76 meters high, and 1,00,000 tons heavy in particular.

The Gerald R.Ford will cost $12.8 billion just for labor and materials, plus $4.7 billion already spent on R&D for its carrier class, aka the Ford. It also has several upgraded facilities to provide sailors a higher-quality life aboard, including better air conditioning, many gymnasiums, and recreation areas, as well as quieter sleeping quarters.

Each part of a warship in the Ford class is designed as a full-scale 3D model using the Rapid Operational Virtual Reality system of the Huntington Ingalls Industries. This is also the first US carrier that’s designed with such computerized techniques.

Additionally, this AT technology is used to give the crew aboard more insight into the systems of the ship as well as to improve efficiency.

The Ford’s propellers will help it reach speeds of 56.3 km/h.

Gunners Mate Darius Bloomfield and Gunners Mate 1st Class Ernest Quinones handle one of the .50-caliber machine guns on the Ford during a general quarters drill.

And in the following picture, a Fire Controlmen team on the Gerald R.Ford is putting dummy ammunition into the MK-15 close-in weapon system on the ship in a maintenance check.

Onboard the Ford is the Rolling Airframe Missile launching system, which can be operated with remote control. Each missile is 73.5 kg, featuring infrared homing capabilities.

Apart from guns for defense and offense, the Ford also has M-14 rifles that are loaded with a throwing kit called Mark-87, assisted with the PCU Gerald R. Ford’s mooring.

The Ford has a Primary Flight Control, also known as the tower, where the air officer and an assistant manager, approve aircraft operations within 8 kilometers from the ship’s deck.

Beneath the Primary Flight Control is the control center, also known as the ship’s bridge. This is where the caption controls the ship, the helmsman is in charge of the actual steering and the lee helmsman is in charge of the speed of the ship from the engine room. The ship’s navigation is tracked by the Quartermaster of the Watch.

Plane launches on the Ford are assisted by the Electromagnetic Aircraft Launching System (EMALS), which was previously done by a steam catapult system. The new technology can accelerate an object that weighs 45 tons to a speed of 200 km/h in under 91 meters.

The heaviest component of the Ford is the gallery deck to flight deck bridge at 1,025 tonnes, measuring 39 meters in length, 39 meters in width. It also houses catapult systems, jet fuel and firefighting systems.

The lower bow of the Ford weights 680 metric tons while its upper bow weighs 787 metric tons.

The Ford’s anchor has a massive weight of 13.6 tonnes, whose chain measures 439 meters in length.

On flight deck crews on the Ford wear uniforms with different colors based on their duties. For example, aviation fuel handlers are in purple uniforms, aircraft handling officers are in yellow uniforms while crash and salvage crews are in red uniforms, and phone talkers or messengers are in blue uniforms.

It took 120-170 workers and 7.57 lakh liters of paint to cover this ship. In the picture below, the Ford is covered with self-heating coating to help it resist UV rays as well as heat.

Compared with older Nimitz designs, the Ford will need 30% less maintenance meaning more cost saved.

Starting August 2015, about 1,600 sailors started working, living on the ship under the testing process. The team preparing food for the sailors even includes culinary specialist and there is a store where they can buy food and stuff just like at home. There are also dental, religious services aboard the ship.

Here are some more photos of the ship.

Featured Stories

Features - Jan 29, 2026

Permanently Deleting Your Instagram Account: A Complete Step-by-Step Tutorial

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Read more

Mobile- Feb 16, 2026

Xiaomi Launches Affordable Tracker to Compete with Apple's AirTag

For users tired of ecosystem lock-in or high prices, the Xiaomi Tag represents a compelling, no-frills option that delivers core functionality at a fraction of the cost.

ICT News- Feb 18, 2026

Google's Project Toscana: Elevating Pixel Face Unlock to Rival Apple's Face ID

As the smartphone landscape evolves, Google's push toward superior face unlock technology underscores its ambition to close the gap with Apple in user security and convenience.

Mobile- Feb 17, 2026

Anticipating the Samsung Galaxy S26 and S26+: Key Rumors and Specs

The Samsung Galaxy S26 series is on the horizon, sparking excitement among tech enthusiasts.

Comments

Sort by Newest | Popular