We Can Now Make Cables From Wood That Will Degrade On Its Own When Thrown Away

Dhir Acharya - Dec 06, 2019

Wood-base fiber cables will save us from dumpsters filled with electronics waste that takes thousands of years to degrade if they ever do.

- Google To Launch A $47-Billion Undersea Internet Cable Project

- Apple's USB-C Drives Queen's Guitarist Brian May Angry

Technology is developing quickly, meaning the device you’re using now may be thrown away in a year, or even months if you like catching up with new tech that’s coming out every day. But that has led to dumpsters filled with electronic waste that is rarely recycled properly, hence damages to the environment and a waste of resources.

With that in mind, researchers from Finland has come up with a way to create fiber optics using wood-based fibers that will break down itself when thrown away.

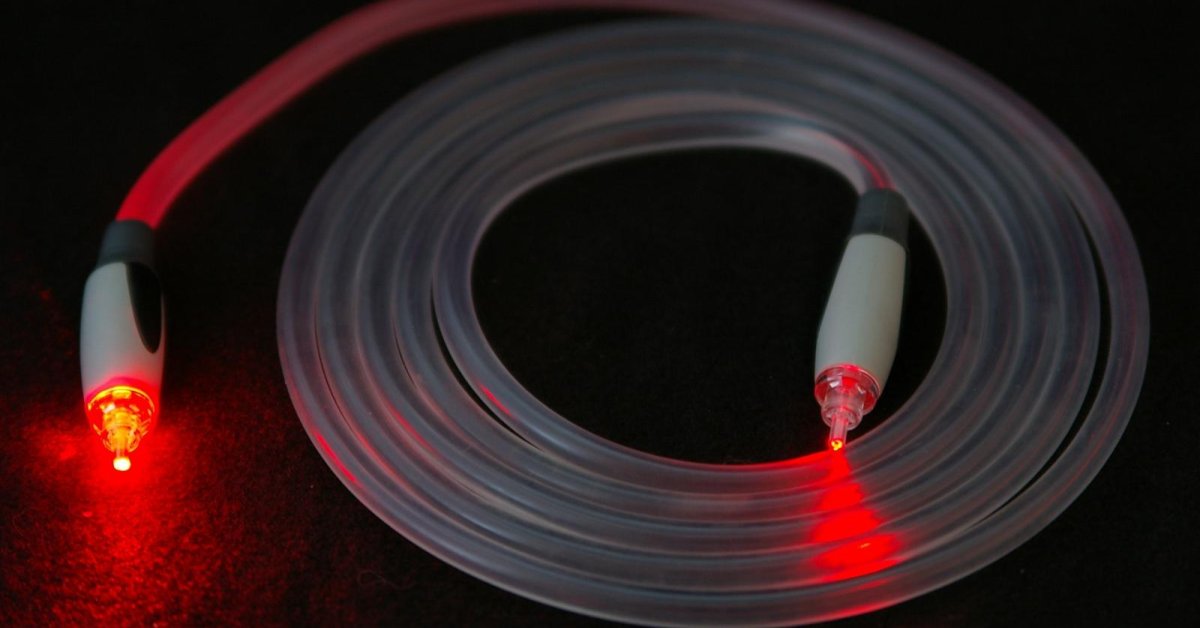

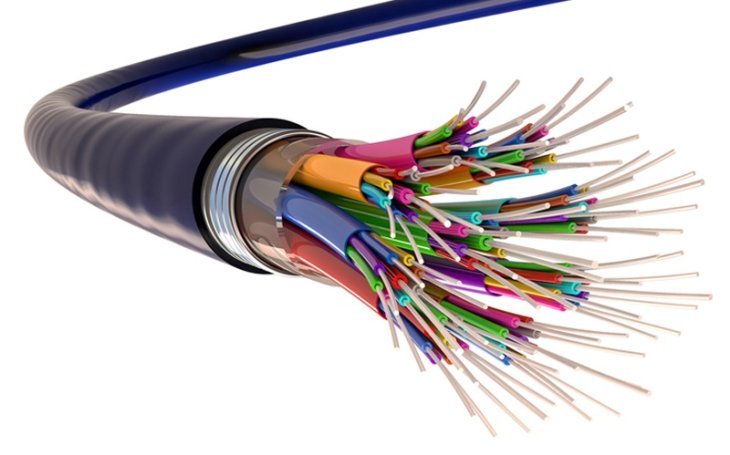

Fiber optic cables are the secret behind modern tech electronics and devices. While metal wires carry electrical signals, optic cables consist of long, thin, plastic or glass threads transmitting pulses of light for kilometers, which connects countries, cities, and data centers. Pulses of light are not flowing electrons, they travel down the optic cables using the total internal reflection process in which photons bounce off the transparent fibers’ inner walls and remain inside the fibers as they travel from one and of the fiber to the other.

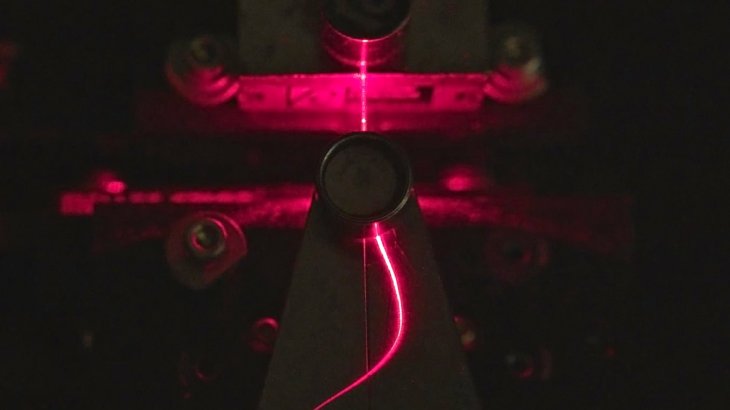

To transmit data with the fewest errors possible, the fibers need to be perfect optically, which seems impossible for wood-based fibers. However, wood is not necessarily opaque, and photons can pass through it depending on the thickness, its moisture, as well as what materials are added to it.

The researchers at VTT Technical Research Centre of Finland has created optic fiber cables from wood-based cellulose: a structural material that enables plants to stand up straight. In the manufacturing process, the research team had to treat the material with salt-based ionic solvents, then they wrap it with a cellulose acetate outer layer that has a lower infraction index compared to the core. The result is that, in plastic or glass fiber optic cables, photons bounce around inside the cable and stay trapped.

But it will take wood-based fiber cables long to completely replace the existing materials and its current ability to transmit pulses of light is not as good as plastic or glass. However, it has its unique characteristics making it useful for various applications as the researchers make it perform better. Fibers made from wood can absorb water, which impacts its ability to transmit pulses of light. But from that, we can see an application immediately, which is moisture sensors for wood-based structures as well as other materials not resistant to water.

Featured Stories

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Features - Jun 16, 2025

Comments

Sort by Newest | Popular