New Lithium-Ion Battery Allows Charging A Car In 10 Minutes For A 350Km Drive

Dhir Acharya - Nov 12, 2019

The key here is to elevate the temperature to raise the reaction rate then cool it during discharge, according to the engineers that developed the battery.

- Battery Bike: How Much Does The Battery Cost? What Type Is The Best?

- This Electric Car Battery Takes Only 5 Minutes To Recharge

- Looking For The Best Electric Bike In India 2021? Take A Look At These

Mechanical engineers from a university say that they have created a lithium-ion battery that a 10-minute charge is enough to power a car on over 350 kilometers of driving.

The key here is to elevate the temperature to raise the reaction rate then cool it during discharge, the team says.

Currently, the temperature at which lithium batteries are charged then discharged remains the same to avoid lithium plating, which is when lithium deposits build up on the anode surface decreasing cell capacity and causing electrical spikes.

But the engineering team discovered that they could avoid the issue if they push the temperature to 60 degrees C for some minutes.

Team member Chao-Yang Wang said hat the key here is to realize rapid heating, or the battery will remain at the elevated temperature for too much time, which causes severe degradation.

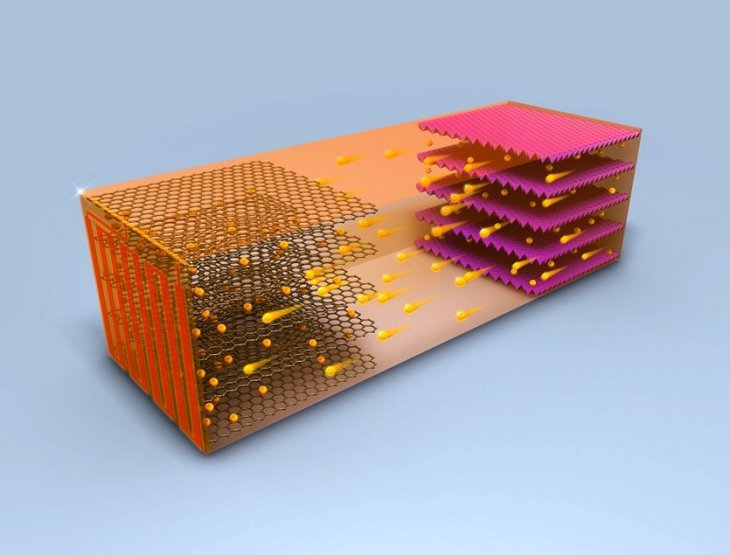

For this to be done, a self-heating nickel structure was developed, which preheats in under 30 seconds. The team tested it by charging three graphite pouch cells that were designed for electric vehicles at 60, 49, and 40 degrees, along with a control at 20 degrees.

They noticed the batteries that were pre-heated to 60 degrees were able to sustain 1700 cycles of super-fast charging while the control cell was able to sustain for 60 cycles. With the average charging temperature from 49 to 60 degrees, they didn’t spot any degradation.

Wang says:

According to the researchers, we can scale up this technology as the cells are based on electrodes that are currently available in industries; and they have already illustrated its use in large-scale modules, cells, and battery packs.

With the use of nickel foil, the cost for each cell rises by 0.47 percent, but since the design doesn’t need external heaters, it overall reduces the cost for making each pack.

Featured Stories

Features - Jan 29, 2026

Permanently Deleting Your Instagram Account: A Complete Step-by-Step Tutorial

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Read more

ICT News- Feb 21, 2026

AI Coding Agent Causes Major AWS Outage at Amazon

In a striking example of the risks associated with deploying advanced AI in critical systems, Amazon Web Services (AWS) recently faced multiple outages attributed to its own AI coding assistants.

ICT News- Feb 20, 2026

Tech Leaders Question AI Agents' Value: Human Labor Remains More Affordable

In a recent episode of the All-In podcast, prominent tech investors and entrepreneurs expressed skepticism about the immediate practicality of deploying AI agents in business operations.

ICT News- Feb 22, 2026

Which AI Model Excels at Which Task in 2026: A Comprehensive Guide

In 2026, the best AI depends on your needs: Gemini for multimodal and speed, Claude for coding and reasoning, GPT for creativity, and Grok for straightforward tech insights.

Comments

Sort by Newest | Popular