'Metallic Wood' Is Our Next Innovative Material, Better Than Titanium

Dhir Acharya - Jan 31, 2019

A team of researchers has developed a new material - metallic wood - which looks like wood but strong like titanium and 4-5 times lighter.

- Bengaluru Engineers Have Created A New Plastic That's Strong Like Steel Yet Lightweight

- Scientists Has Created The New Blackest Material Ever, Absorbing 99.96% Of Incoming Light

- Origami-Inspired Metamaterial Can Help Reduce Crash Damage

Titanium is an impressive metal that is equally strong but half as heavy as steel. However, scientists say they can do even better than that.

A research team including scientists from the University of Illinois, University of Pennsylvania, and the University of Cambridge has built a nickel sheet with nanoscale pores which make it equally strong but four or five times as light as titanium. The journal Nature Scientific Reports published their paper.

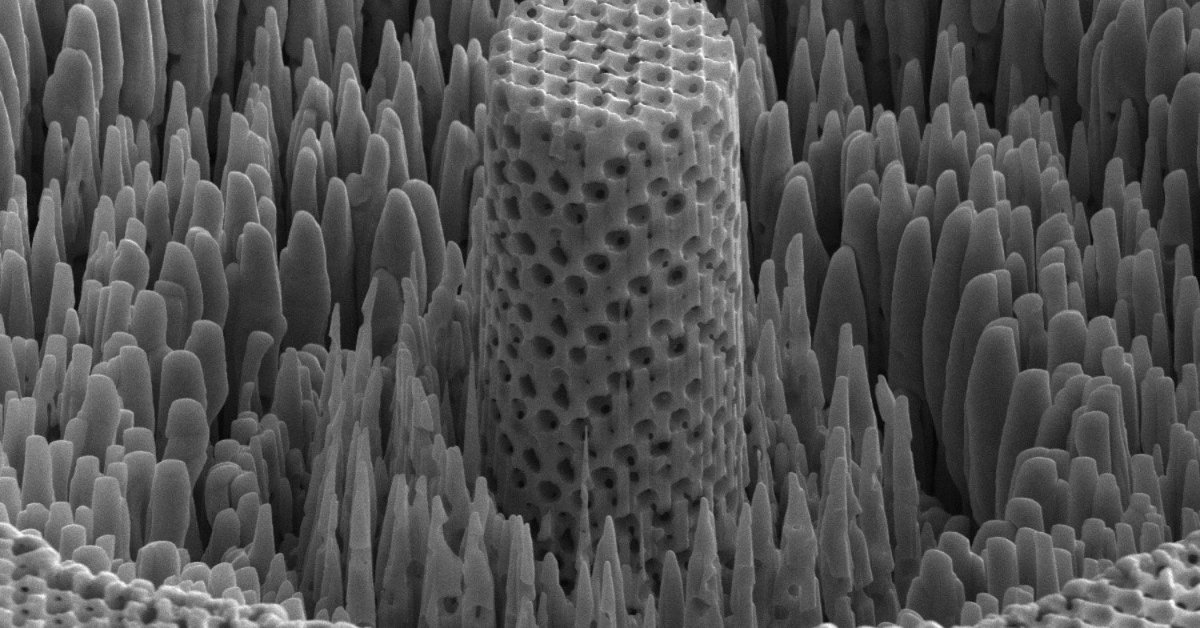

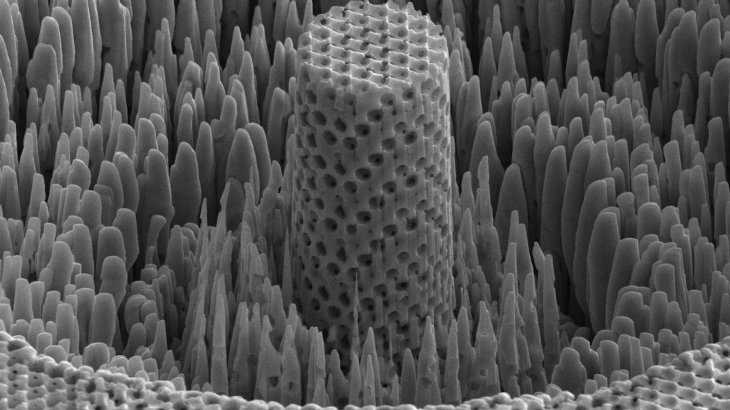

A sample of the "metallic wood"

Since the pores are made in a self-assembly process and there is empty space, the material looks natural, like wood.

According to the researchers, the empty space of this “metallic wood” allows infusing it with other materials, similar to porous wood grain transporting energy. For instance, the scaffolding can be infused with cathode and anode materials to make a prosthetic leg or plane wing.

Research lead James Pikul from Pennsylvania said that the term “metallic wood” is based on the material’s density which is similar to wood and its cellular nature.

In cellular materials, there are thick and dense parts to hold the structure, along with porous parts that support biological functions such as transporting from and to cells.

Pikul added that “metallic wood” has a similar structure, but they’re working to maximize the strength of struts. Apparently, there are atomic arrangement defects in even the best metals of nature, if we can avoid or fix the defects, we can limit the limits.

The researchers also stated that a titanium block with a perfect arrangement of atoms and their neighbors will be ten times more powerful than normal.

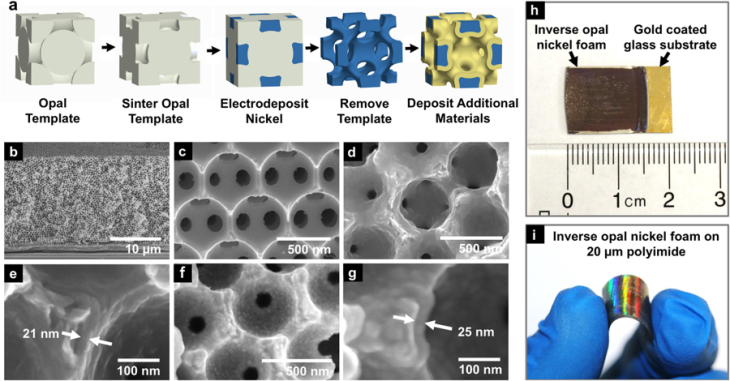

The fabrication process for a unit cell of the material

Exploiting this phenomenon under architecture approach, material scientists have been designing structures in which they control the geometric arrangement to unlock the mechanical characteristics which arise at the nanoscale, reducing defects.

According to Pikul, smaller structures can be stronger, but so far, no one can make something large enough for practical use. Currently, most samples generated from strong materials are as small as a flea, and the team can make something 400 times bigger with metallic wood.

The researchers have this approach from nanometer plastic spheres suspended in water which, after the water evaporates, settle and stack like cannonballs to create an orderly, crystalline framework.

They use electroplating to infiltrate nickel into the plastic spheres. When the nickel is in place, they dissolve the plastic sphere with a solvent, revealing an open network of metallic struts.

Since the resulting material includes 70 percent empty space, its density is dramatically low relative with its strength. With this level of density, the metallic wood brick would float. However, bringing this production process into commercial purposes is challenging due to limited infrastructure.

If the team can make larger samples from metallic wood, they can head to macroscale tests to find out how much larger the material can go, which is critical.

Pikul said they need to understand how metallic wood’s struts defects can influence the material’s overall properties.

Featured Stories

Features - Jan 29, 2026

Permanently Deleting Your Instagram Account: A Complete Step-by-Step Tutorial

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Read more

Mobile- Feb 16, 2026

Xiaomi Launches Affordable Tracker to Compete with Apple's AirTag

For users tired of ecosystem lock-in or high prices, the Xiaomi Tag represents a compelling, no-frills option that delivers core functionality at a fraction of the cost.

Mobile- Feb 17, 2026

Anticipating the Samsung Galaxy S26 and S26+: Key Rumors and Specs

The Samsung Galaxy S26 series is on the horizon, sparking excitement among tech enthusiasts.

ICT News- Feb 18, 2026

Google's Project Toscana: Elevating Pixel Face Unlock to Rival Apple's Face ID

As the smartphone landscape evolves, Google's push toward superior face unlock technology underscores its ambition to close the gap with Apple in user security and convenience.

Comments

Sort by Newest | Popular