Indian Startup Boosts Crop Yields And Quality By Using AI

Dhir Acharya - Nov 30, 2018

Imago AI, a one-year-old Indian startup has created a technology to boost crops yield, seed quality, plant's disease-resistance and more.

- Which AI Model Excels at Which Task in 2026: A Comprehensive Guide

- AI Coding Agent Causes Major AWS Outage at Amazon

- Tech Leaders Question AI Agents' Value: Human Labor Remains More Affordable

November 29, in the 2018 TC Disrupt Berlin Battlefield, India took the stage. Imago AI, an agtech startup from India is making use of AI to increase crop yields as well as reduce food waste.

The Delhi-based team automates and speeds up the process of measuring the amount and quality of harvest with machine learning techniques and computer vision.

Producing higher-quality seed in a shorter time

At present, it takes somewhat six to eight years for companies to generate a new variety of seeds, but the team’s new technology will cut down this process by at most 75 percent, increasing the efficiency of measuring crop traits.

In one pilot conducted with grading the crops, it took a client two days for a manual process using scales, as opposed 30 to 40 minutes for using the AI system, Abhishek Goyal – the startup co-founder – recalled.

Thanks to the image processing technology based on AI, they are also able to gather more data compared to human eyes as the algorithm can not only measure but also tell the differences in finer-grained phenotypes better than humans do.

Co-founder Shweta Gupta added there a few phenotypic traits that you cannot identify manually, but AI can. Hence, we can cover a broader range of phenotypic characteristics, which results in more options for the next cycle of the seed. In the long term, we will have higher quality seeds.

The lengthy name for this technology is “High throughput precision phenotyping”, which is actually data-mining the parameters of crop qualities by using AI.

According to Gupta, plant breeding is a critical, yet costly and complicated process that requires plenty of human resources and time. To generate the rice with the standard we eat today, companies have spent seven to eight years on development.

The outstanding advantage of AI does not only lie in higher-yielding crops, higher-quality seed, and a faster process but also in its ability to gain critical predictive insights.

Choosing the best crops for a particular location and climatic condition, and still, in a shorter time

This means that if the team can find the correlation between the genotypic of the plants and geotagged phenotypic measurements, this AI method can tell farmers, based on location as well as climate condition, what crop variety is the best to use. While, currently, genetic engineering is being used in picking the best crop, which has raised controversy over food safety.

Goyal told that before establishing the correlation to help firms significantly decrease the time to produce seed, they need to collect enough precise phenotypic data. And once the correlation is established, the team can assist seed companies in predicting phenotypic data regarding their genomics data and environmental conditions.

The highly accurate correlation will save a lot of research time for companies, and they don’t have to do field trials. Also, if the chosen varieties can resist diseases better, farmers can use less pesticide.

All in all, the amount of time for seed production can fall by half, resulting in three or four years max.

Picking crops with better resistance to diseases

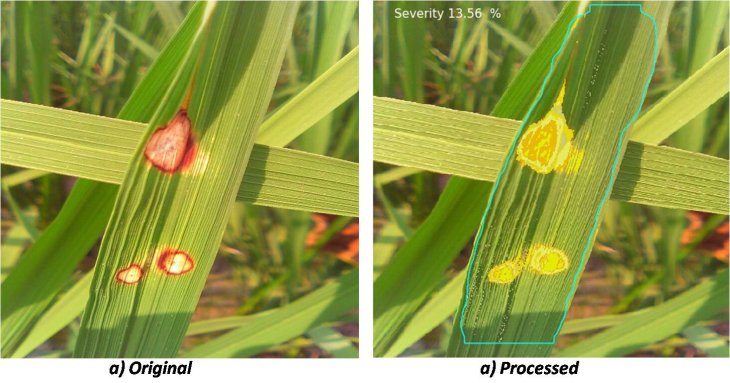

Beside crop yields and crop qualities, the team is also using AI and computer vision in detecting diseases affecting crops, then measure how much each plant is affected at higher precision.

Provided that the world currently loses about 40 percent of total crops every year due to diseases, this key point seems to help pick better disease-resistant crops.

And once again, this AI-based image analysis can outperform the human eye, providing more uniformly consistent data. Eventually, that will add to improving the whole production cycle.

Current trials in India and the US

For now, Imago AI is working on data gathered from several trails with seed firms, including DuPont Pioneer that is a recurring paying client as well as some paid trials conducted with other seed companies that cannot be named here.

India and the US are the locations for these trials. Goyal said that they don’t necessarily do trials in every country since the companies they’re working with are global, presenting in 30 or 40 countries. The companies can do tests in one country then easily implement the technology in others.

No particular camera hardware required

Notably, there’s no certain standards or limits to the camera used in this imaging technology, tablets, smartphones, drones or satellite images don’t matter.

However, in some cases related to crop traits such as length, to capture the object, we may need to either adjust the distance from the camera to the object or place a reference object or do both.

Imago AI’s competitive advantages

There are other image-analyzing applications available in the market too.

Yet, founders of Imago AI argue that those competitor applications are not fully automated which requires a lot of data inputted manually. In contrast, their technology needs only one manual step for selecting the target crop.

In addition, Imago AI’s approach is completely safe as they don’t have to pluck the plant and taken to the lab. Instead, their algorithms can take pictures and automatically remove the background noise, extracting the sample’s image precisely.

Plus, researchers will also get mathematical tools besides the software itself, which can be used in analyzing phenotypic data and allows exporting Excel files. This is additional support from the team.

How accurate is Imago AI?

As stated by Goyal, in terms of measuring, the results obtained from Imago AI’s technology achieved over 99 percent accuracy, in comparison with those from manual activities.

As for illustrating disease spread, Goyal said manually generating exact measurement is just impossible. An expert can only provide a range of disease severity, which is from 25 to 40 percent, while Imago can provide an exact number, 32.23 percent for example.

Further and future application

Not only in seed producing and crop yielding this technology can also help in food production. The hyper-spectral imaging data and computer vision can detect foreign materials in foodstuffs on a production line, which eventually reduces the amount of food wasted during production.

In the next one year, Imago AI expects to have their technology used in somewhat 40 or 50 companies globally.

Featured Stories

Features - Jan 29, 2026

Permanently Deleting Your Instagram Account: A Complete Step-by-Step Tutorial

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Read more

ICT News- Feb 22, 2026

Which AI Model Excels at Which Task in 2026: A Comprehensive Guide

In 2026, the best AI depends on your needs: Gemini for multimodal and speed, Claude for coding and reasoning, GPT for creativity, and Grok for straightforward tech insights.

ICT News- Feb 23, 2026

It's Over for Xbox: Asha Sharma Takes Over to Ruin Microsoft Gaming with AI

It's not just a leadership change; it's the death knell for Xbox.

ICT News- Feb 21, 2026

AI Coding Agent Causes Major AWS Outage at Amazon

In a striking example of the risks associated with deploying advanced AI in critical systems, Amazon Web Services (AWS) recently faced multiple outages attributed to its own AI coding assistants.

Comments

Sort by Newest | Popular