Modular Hospital Rooms: The Future Of Healthcare Facilities

Dhir Acharya - Feb 17, 2021

Modular hospital rooms have been around for a long time but have never really become widely used. So, how are they better than conventional construction?

Modular construction in the healthcare field is a design concept that has been discussed a lot but has not seen large-scale implementation. In fact, modular hospital construction appeared in 1855 when prefabricated building sections were used in designing and constructing a British Army hospital. In this post, we will discuss modular hospital rooms in the present day.

Table of Contents

What is modular construction?

According to the Modular Building Institute, modular construction is a process where a building is built off-site, under controlled plant conditions, constructed with the same materials, codes, and standards applied for conventionally built facilities.

Parts of the building are conducted in a manufacturing-style environment like that for airplanes, cars, and other large machinery. Then, the construction is moved to the project site to be installed. The methodologies and materials used are the same as conventional on-site construction and must meet the current building standards and codes.

The Modular Building Institute says that modular construction is greener, smarter, and faster than traditional construction.

Modular hospital rooms are the ones built in this method.

What are the benefits of modular hospital rooms?

As stated in the previous section, modular hospital rooms have several benefits over conventionally built construction.

First of all, this construction method allows for shortening construction schedules and reducing costs. Exam rooms, patient bathrooms, patient-overhead utilities, and single-toilet rooms can all be prefabricated off-site then brought to the project site to be installed. Even a simple item like the patient headwall can be prefabricated off-site and later installed at the construction site.

Secondly, each component is under the same assembly plan, using the same materials, and inspected in a quality control program before the installation process. This way, the quality is guaranteed, which eventually drives down the wasted material amount and enhances project safety.

The construction method also helps decrease the overall project schedule. During the prefabrication process, other activities like foundation, site, and structural work can take place. Once the components are completed, they are shipped and installed at the construction site. This results in a far shorter construction time and reduces the need for onsite coordination between parties.

Engineers, architects, and contractors report higher productivity, quality, greater schedule certainty, enhanced cost predictability, less construction waste, higher client satisfaction, as well as improved safety, according to Dodge Data & Analytics. All in all, these lead to a lower overall project spending for the owner.

Since all components are constructed with the same design, the coordination process on site is omitted from the portions of the prefabricated buildings now that trades can coordinate off site in the pre-fabrication process. Using Building Information Modeling (BIM), trades can streamline the pre-fabrication process and come up with a repeatable, design that’s easy to construct.

For each prefabricated module to be constructed off-site, there can be a full, specific BIM model. In the BIM process, trades can coordinate their installation, which will help streamline each component’s manufacturing. Such a construction mechanism greatly reduces the effort required while improving the project schedule.

How much does a private room in the hospital cost?

A private room in the hospital costs around $400 per day, offering a bed along with a private bathroom. Meanwhile, a semi-private hospital room that consists of two beds with a shared bathroom for two patients may cost around $300 a day.

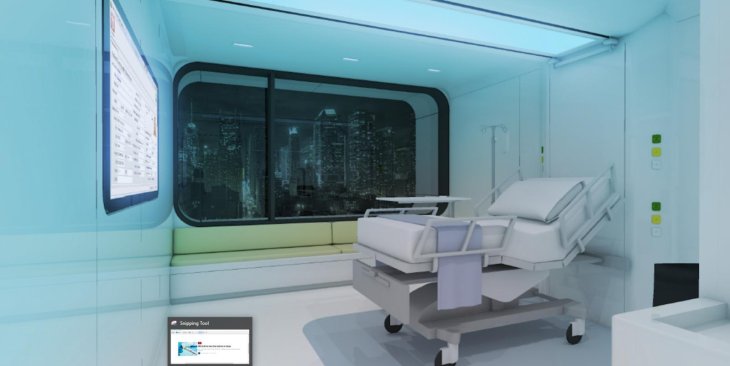

MedModular hospital rooms

MedModular is a modular hospital room created by EIR Healthcare that you can buy on Amazon. In early 2019, CNBC reported that the smart hospital room was available on the world-leading e-commerce platform at a price of $285,000.

At $814 per square foot, the company claims the MedModular is cheaper than traditional construction, featuring a customizable design but every room comprises a bed and a bathroom.

While costing a hefty amount, this product is targeted to business buyers, according to EIR Healthcare CEO Grant Geiger.

“We’re targeting hospitals and health systems. There’s a trend towards bringing more transparency in the health care space.”

He added that he was observing an increase in hospitals’ interest in using these units for a hospital emergency room or simulation lab. Besides, he has considered looking into potential military customers.

However, it’s obvious he needed to start with hospital administrators as Amazon has been selling medical supplies to them, including bedpans and syringes. In the past, large hospital systems used to purchase via group purchasing organizations (GPOs), which offered discounts. But this method lacked transparency around costs.

Before being able to sell his modular hospital rooms on Amazon, Geiger had to talk to that group for months. He also had to obtain the approval to ship and deliver the product, in which these units are transported in giant shipping containers on the freeway.

>>> With The New Coronavirus Variants, You Must Wear At Least Two Masks

Featured Stories

Features - Jan 29, 2026

Permanently Deleting Your Instagram Account: A Complete Step-by-Step Tutorial

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Read more

Mobile- Feb 16, 2026

Xiaomi Launches Affordable Tracker to Compete with Apple's AirTag

For users tired of ecosystem lock-in or high prices, the Xiaomi Tag represents a compelling, no-frills option that delivers core functionality at a fraction of the cost.

Mobile- Feb 17, 2026

Anticipating the Samsung Galaxy S26 and S26+: Key Rumors and Specs

The Samsung Galaxy S26 series is on the horizon, sparking excitement among tech enthusiasts.

ICT News- Feb 15, 2026

X Platform Poised to Introduce In-App Crypto and Stock Trading Soon

X has been laying the groundwork for this expansion.

ICT News- Feb 18, 2026

Google's Project Toscana: Elevating Pixel Face Unlock to Rival Apple's Face ID

As the smartphone landscape evolves, Google's push toward superior face unlock technology underscores its ambition to close the gap with Apple in user security and convenience.

Comments

Sort by Newest | Popular