Step Closer To Life In Mars Through 3D Prints From Simulated Lunar Soil

Indira Datta - Dec 01, 2018

Because of the need for available Mars materials to study, scientists have diverted their research to lunar regolith, lunar soil's simulated version.

- Believe It Or Not, Dirt From Mars Can Be Bought With Only $20 A Kilogram

- Elon Musk Doesn't Buy Luxury Vacation Homes, Here's How He Spends His Money

- India’s First 3D-Printed Building With Indigenous Construction Materials

Searching for life on Mars has long been one of the scientists' interests, but the lack of resources needed to sustain human life on Mars is a difficult challenge. Astronauts trying to invade, or just pay a visit to the red planet with limited supply with them pose an even more difficult challenge. Scientists are trying to study the limiting materials that exist on this red planet. Finding the use of available materials on Mars to survive is one of the biggest challenges while visiting our neighboring planet. But recently, the latest European Space Agency experiment on 3D - printing has shown that this plan is not impractical.

Although there are a lot of rovers and probes sent to Mars to retrieve samples for this research, so far, none of them has returned yet. Our knowledge of Mars is limit to what Opportunity and Spirit have discovered. And current researchers can only learn and explore the patterns and meteorites that have fallen to Earth by themselves. The only thing we can count on is that just like the Moon, Mars also has a massive amount of dust. Instead of just focusing on genuine Mars materials, scientists have diverted their research to lunar regolith, lunar soil's simulated version.

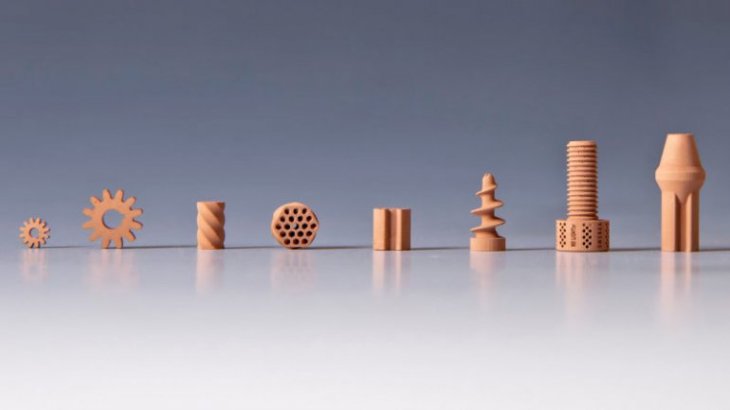

The ESA partnered with Lithoz, an Austrian company to 3D-print a sample of various parts. To produce these 3D versions, a binding substance which is sensitive to light was mixed with the regolith. Regolith that comes in the form of very fine dust is comprised of aluminum, iron oxides, silicon, and calcium.

In this experiment, researchers do not use a conventional method of heating the mixture, pushing it out like hot glue and then leaving it cool and harden. This 3D - printing technique creates very thin layers of regolith which are then undergone a light exposure process, from which the binder becomes solid.

These solid or ceramic parts produced from the furnace heat are not only durable but also have a smooth surface. Thanks to this, the components are made of high precision, high compatibility between parts and make the assembly easier. ESA then tests the durability and endurance of these 3D printed parts. Because they will be traveling in space and placed in harsh environments outside the universe.

If it can work well, then the astronauts do not have to travel with a trailer that is full of spare parts but instead carries one 3D printer, a digital repository, and maybe a bucket of dust.

Thanks to 3D-printing technique, we can create all the needed items such as clothing, solar panels, equipment, useful tools. Moreover, it may also produce nutrients and food ingredients in the future.

Additionally, lunar regolith can also be used to reuse and recycle item from Earth. This helps both to build a life outside the universe and to reduce pollution and waste on Earth.

Featured Stories

ICT News - Jul 05, 2025

Windows 11 is Now the Most Popular Desktop OS in the World

ICT News - Jul 02, 2025

All About Florida’s Alligator Alcatraz: A Smart Move for Immigration Control

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

ICT News - Jun 24, 2025

Tesla Robotaxi Finally Hits the Streets: $4.20 Rides That'll Make You Hold Your...

ICT News - Jun 24, 2025

World's First Flying Humanoid Robot Takes Flight

ICT News - Jun 24, 2025

When Closed Source Met Open Source: Bill Gates Finally Meets Linus Torvalds After...

Gadgets - Jun 23, 2025

COLORFUL SMART 900 AI Mini PC: Compact Power for Content Creation

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

ICT News - Jun 20, 2025

Tesla vs Zoox vs Waymo: Who would win?

ICT News - Jun 19, 2025

Comments

Sort by Newest | Popular