3D Printer Can Now Print Metal Car Parts Right When You’re In The Store

Author - Oct 16, 2018

3D Printer can now print metal models to help produce machines as easy as plastic products.

- India’s First 3D-Printed Building With Indigenous Construction Materials

- KFC Plans To Make 3D-Printing Chicken And Add It To Their Menu

- Scientists Use Math To 3D Print The World's Strongest Steel

The 3D printing technology nowadays allows us to print almost anything we want. From concrete-made houses to cornea made from bio-ink. The 3D printer can print anything for you without any problems.

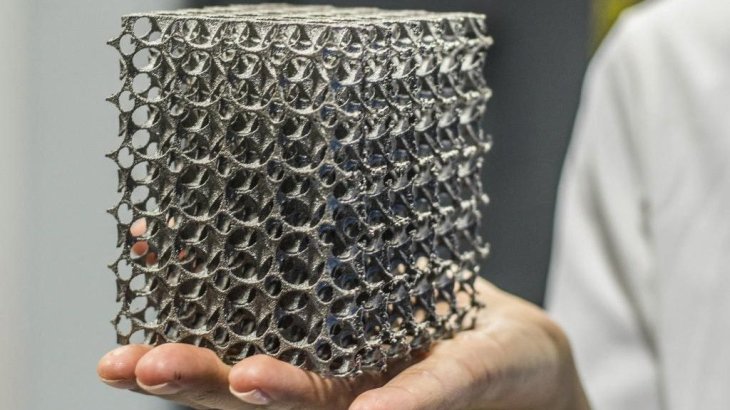

However, not every material makes it easy for the 3D printers to produce the best models. One of those materials is metal. Printers used for industrial purposes are able to perform the task, but for commercial ones, it’s still a little bit complicated and hard to complete easily, compared to printing plastic models.

The good news is Yale University’s researchers believe that it is possible to make producing metal objects easier for commercial printers. Their study is shown in the Materials Today last Tuesday.

How does it work?

The biggest obstacle when dealing with metals is that it is not easy to find or keep them at a suitable state for printing. We need to get the material soft enough to shape them as our wish, which is a lot easier to do with plastic than metal. To solve this problem, researchers started using BMGs ( Bulk Metallic Glasses).

BMG is a kind of metal which doesn’t exhibit the similar rigid structure of atoms compared to most other metal alloys. That means we can soften it without all the struggles. It is, however, still very strong and has a high level of elastic limits, corrosion resistance and last but not least, fracture toughness - which are some of the typical features of metals

In the study, Yale’s researchers concentrated on an available BMG consisting of zirconium, copper, beryllium, titanium, and nickel. Just like making 3D models from plastics, the researchers softened rods made from their BMG by putting them in a feeding system that was heated to 460°C

That process allowed them to print several different models using a strong metal.

The great news is that the researchers announce that they have succeeded in testing the system with many other types of BMGs. Their next goal is to “making the process more practical- and commercially-usable,” - said Jan Schroers - a researcher in an interview.

There are countless ways to put printers that produce metal simples into practice. Mechanics can now change the exact car part you need right at their store at any given time. Makers can print whatever they need to complete their project right at their place. In the end, this research is the beginning of a whole new era for 3D printing, from plastic to metal.

Featured Stories

Features - Jan 29, 2026

Permanently Deleting Your Instagram Account: A Complete Step-by-Step Tutorial

Features - Jul 01, 2025

What Are The Fastest Passenger Vehicles Ever Created?

Features - Jun 25, 2025

Japan Hydrogen Breakthrough: Scientists Crack the Clean Energy Code with...

ICT News - Jun 25, 2025

AI Intimidation Tactics: CEOs Turn Flawed Technology Into Employee Fear Machine

Review - Jun 25, 2025

Windows 11 Problems: Is Microsoft's "Best" OS Actually Getting Worse?

Features - Jun 22, 2025

Telegram Founder Pavel Durov Plans to Split $14 Billion Fortune Among 106 Children

ICT News - Jun 22, 2025

Neuralink Telepathy Chip Enables Quadriplegic Rob Greiner to Control Games with...

Features - Jun 21, 2025

This Over $100 Bottle Has Nothing But Fresh Air Inside

Features - Jun 18, 2025

Best Mobile VPN Apps for Gaming 2025: Complete Guide

Features - Jun 18, 2025

A Math Formula Tells Us How Long Everything Will Live

Read more

ICT News- Mar 01, 2026

Samsung Links Galaxy S26 Price Hikes to AI Memory Supply Issues

This development highlights the broader challenges faced by the tech industry as it integrates artificial intelligence into everyday consumer electronics.

ICT News- Mar 02, 2026

IDC Report Predicts Surging Smartphone Prices Due to Global RAM Shortage

This development underscores the broader ripple effects of the AI boom on everyday technology, highlighting the interconnected nature of global semiconductor supply chains.

ICT News- Mar 03, 2026

Budget Entry-Level PCs Under $500 to Vanish by 2028 Due to Memory Price Surge

The era of the sub-$500 PC appears to be ending.

Comments

Sort by Newest | Popular